In industrial processes, steam is commonly used as a heating medium or as a source of energy. However, steam systems can also pose a significant risk of overpressure in case of blocked steam discharge lines. In such scenarios, the pressure inside the equipment can rapidly increase, potentially causing equipment failure, leaks, and even explosions. In such scenarios, pressure relief valves are designed to automatically relieve excess pressure when it reaches a predetermined setpoint.

Table of content:

Overpressure due to blocked steam discharge

Pressure relief valve sizing calculation for blocked steam discharge

PSV sizing calculator – blocked gas discharge

Overpressure due to blocked steam discharge

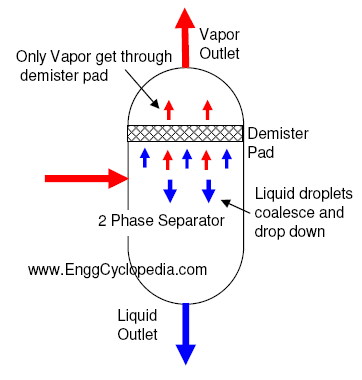

When a steam discharge line is blocked, the steam pressure in the line can increase rapidly, leading to an overpressure scenario. This can be caused by factors such as valve closure or blockage in the downstream equipment. If the pressure in the steam line exceeds the design pressure, it can lead to equipment failure or even catastrophic accidents.

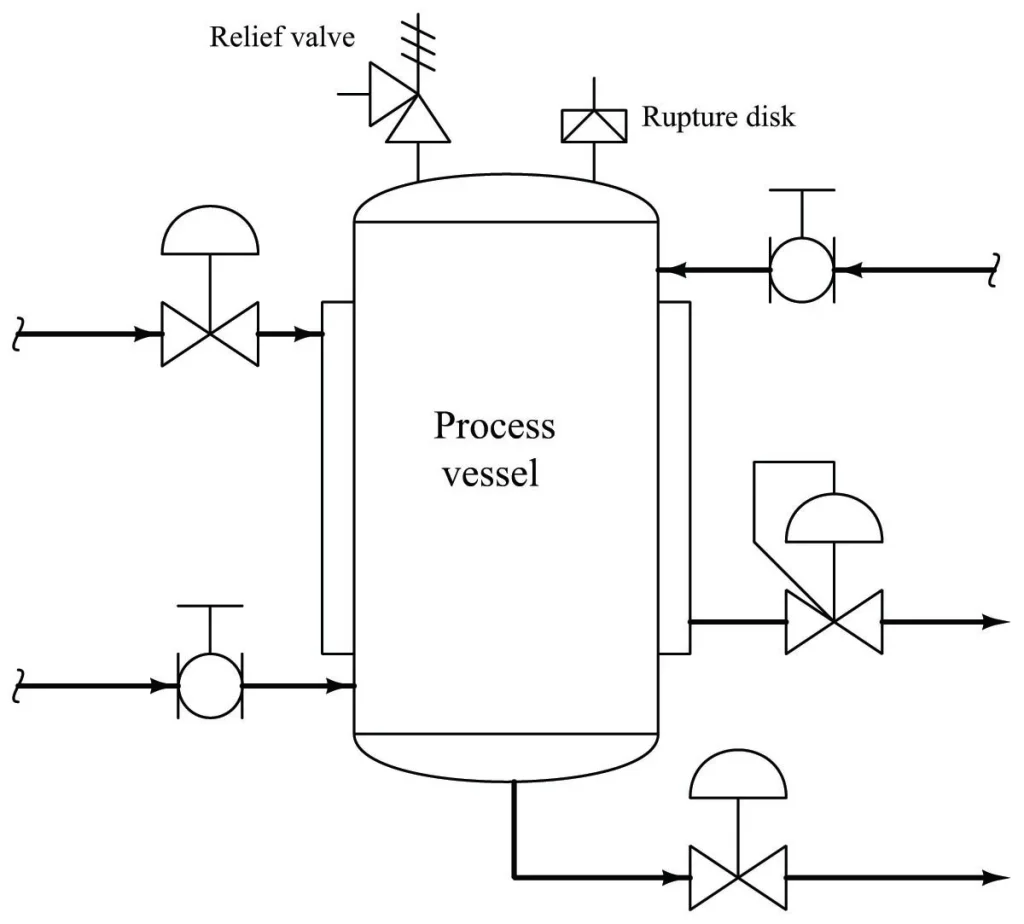

To prevent this, a pressure relief valve (PRV) can be installed to automatically relieve excess pressure when the pressure inside the system reaches a predetermined setpoint. The PRV should be selected and sized based on the specific properties of the steam, such as its temperature, pressure, and flow rate. The required capacity of the PRV should be determined by considering the maximum possible flow rate and the pressure drop across the valve.

Check this post to study more about various overpressure scenarios which are considered for pressure relief valve sizing.

Pressure relief valve sizing calculation for blocked steam discharge

Problem Statement

Design a pressure relief valve for the following service.

Protected equipment : Reboiler

Relief service : Steam

Reason for relief : Blocked steam discharge

Relieving Rate : 10,000 kg/hr

Gas Density : 2.5 kg/m3

Ratio of specific heats for the gas (CP/CV) : 1.3

Compressibility factor of gas = 1.1

Molecular weight of gas = 18 gm/mole

Relieving temperature = 2500C

Set pressure : 5.0 barg

Accumulation : 10%

Back pressure at relief valve discharge : 0.5 barg

Type of relief valve : Conventional pressure relief valve

Solution

This sample problem for relief valve sizing calculation can be solved in following steps, which are based on pressure relief valve sizing procedures described in API RP 520 Part I.

Step1

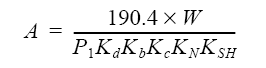

First step is to use the relief valve sizing procedure given in the API 520 part I for steam relief valves. The following equation is used,

... (1)

A : orifice are requirement in mm2

W : flowrate in kg/hr

W = 10,000 kg/hr

P1 : Relieving pressure upstream to relief valve in bara

P1 = 6.51 bara (including 10% accumulation)

Kd : Coefficient of discharge

Kd = 0.975 for gas service

KC : combination correction factor for use of rupture discs

KC = 1 (for absence of rupture disc upstream to the valve)

(If a rupture disc is present, KC = 0.9)

Kb = Capacity correction factor due to back pressure

Kb = 1 (for conventional relief valves with near atmospheric backpressure)

KSH = Superheated steam correction factor

From Table 9 of API 520 Part I,

KSH = 0.9786 (@ 6.0 bara & 250 0C by liner interpolation)

Plugging this data into equation (1), the minimum required orifice area for the relief valve is calculated to be,

A = 32.24 cm2

Step2

The next higher available orifice area should be selected for the pressure relief valve to be actually installed. Referring to the table of standard orifice sizes given in EnggCyclopedia's relief valve sizing calculator, next high available orifice area is selected to be A = 41.20 cm2 and the corresponding designating letter is 'P'. Available valve size is '4P6', which corresponds to different nozzle sizes for suction and discharge nozzles of the pressure relief valve. For a '4P6' valve suction nozzle is of 4" size and discharge nozzle of 6" size.

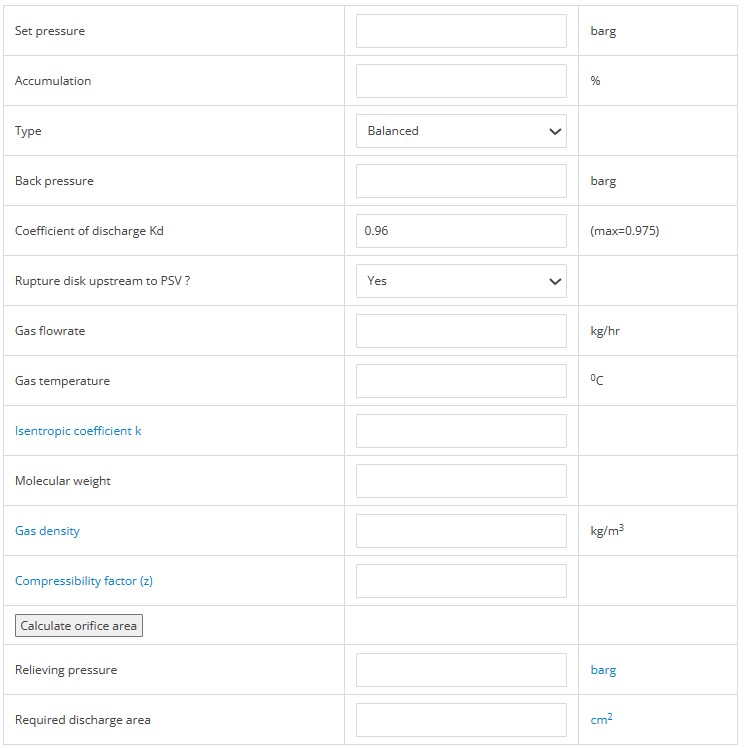

PSV sizing calculator – blocked gas discharge

Check the pressure safety valve sizing calculator for blocked outlet of a vapor filled vessel. The post also contains a table which represents the standard orifices with their designating letters and corresponding area.