Scroll compressors are orbital motion, positive-displacement type compressors that compress gas with two inter-fitting scrolls.

Table of Content:

1. What is a scroll compressor?

2. How does a scroll compressor work?

3. Structure of a scroll type compressor

4. Using valves in a scroll compressor

5. Advantages

6. Disadvantages

7. Applications

8. Selecting a scroll compressor

What is a scroll compressor?

A scroll compressor is a type of positive displacement compressor that uses two interleaved spiral-shaped scrolls to compress gas. The scrolls rotate against each other, trapping and compressing the gas as it moves towards the center of the scrolls.

Scroll compressors are important because they offer highly efficient, reliable, and quiet, making them ideal for a wide range of industrial and commercial applications. They also have a compact design and require minimal maintenance, making them cost-effective in the long run.

How does a scroll compressors work?

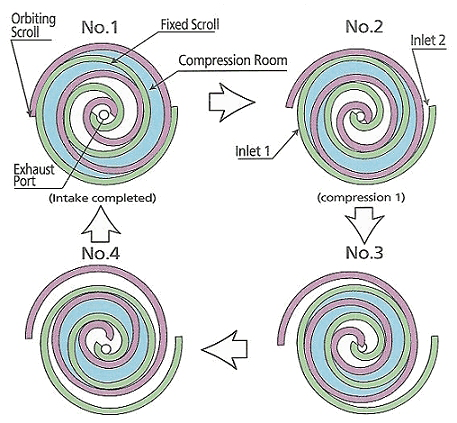

A scroll compressor actually consists of two scrolls or spirals. One scroll is moving, whereas the second one is fixed (attached to the compressor body). The first scroll orbits (rotates) in a path defined by its mating fixed scroll. The orbiting scroll is connected to the compressor's crankshaft.

As a result of the scroll's movement, gas pockets are formed between the two scrolls. At the outer part of the scrolls, the pockets suck in gas and then move towards the center of the scroll, where the compressed gas is discharged. As the gas moves into the continuously smaller internal pockets, both its temperature and pressure are increased. Thus a desirable discharge pressure is achieved by the motion of the compressor scrolls.

Figure 1 - Diagram showing how a scroll compressor works

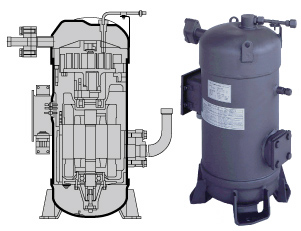

Structure of a scroll type compressor

Scroll compressors are fully hermetic (enclosed in the compressor's shell, which is usually a cylindrical welded steel shell). Majority of scroll compressors used in refrigeration and HVAC services are of vertical orientation, with the scroll sets typically installed on the upper part of the motor shaft.

Figure 2 - Typical scroll compressor diagram

Using valves in a scroll compressor

Normally, suction or discharge valves are not used in these compressors. But dynamic discharge valves are preferred at the compressor discharge, when operating at high differential pressure values. In such scenarios, having a dynamic valve at the discharge increased the efficiency of operating the compressor. For example, scroll compressors operate at high differential pressure, in case of refrigeration applications. In such cases dynamic discharge valves are preferred.

But in other cases, for example - air conditioning, having a discharge valve actually results in pressure losses, reducing the efficiency. Hence these are normally not preferred.

Scroll compressor advantages

Scroll type compressors are inherently more efficient compared to other types of compressors for many reasons:

- The absence of pistons for gas compression enables scroll compressors to reach 100% volumetric efficiency, leading to reduced energy costs.

- Re-expansion losses, a typical feature of each piston stroke encountered in reciprocating models, are eliminated. In addition, valve (ports) losses are eliminated, since suction and discharge valves (ports) do not exist.

- Furthermore, due to the absence of several moving parts, scroll compressors are considerably quieter in operation compared to other types of compressors, like for example reciprocating type ones. Scroll compressors typically make 5 to 15 dBA lower noise than other compressor types.

- Due to lower vibration and noise, they do not need spring suspensions.

- Fewer moving parts, lower vibrations and less friction also means that these compressors are more durable.

- Their weight and footprint are considerably smaller compared to other bulkier types of compressors in use nowadays.

- Gas pulsation is also minimized, if not eliminated and consequently, they can operate with less vibration.

Scroll compressor disadvantages

- Being fully hermetic, perhaps the biggest disadvantage of scroll compressors is that they are generally not easily repairable. They cannot be disassembled for maintenance.

- Many reciprocating compressors are tolerant on rotating in both directions. This is usually not the case for scroll compressors.

- Incremental capacity control on systems with several scroll compressors has proven several times to be problematic as well.

Applications of scroll compressors

Since their introduction, scroll compressors have been successfully used in applications involving food and fruit refrigeration, truck transportation, vacuum pumps, marine containers as well as residential and small to medium scale commercial air-conditioning applications.

Using scroll compressor in HVAC systems

A scroll compressor can be a preferred choice in HVAC systems over other types of compressors, as it has fewer moving parts.

Check why to use scroll compressor in HVAC systems in detail.

Selecting a scroll compressor

When selecting a compressor you can either go for single phase or 3-phase motor for the compressor. It will completely depend on what kind of electricity connection is available. Normally, single phase connections are available. If 3 phase connection is available, then the three phase motor is considerably more efficient.

Next, you should consider the differential pressure and flowrate parameters. There are different scroll compressors available in the market, having different combinations of differential pressure and flowrate values. You should select the one which covers your requirements of certain minimum differential pressure at given flow rate.

Next, you can look at secondary parameters like the noise level etc. depending upon where the compressor is going to be used. If it is going to be used in a residential air conditioner, you will prefer to use a model with lower noise levels.