Commonly asked interview questions for new process engineers or chemical engineers.

Heat Transfer Questions

Q: Why does the ice from refrigerator melt faster than an ice block from an ice factory?

Ans: It is a trick question. Answer does not have anything to do with where the ice was frozen. But rather with the size of the ice cubes and more importantly the surface area of the ice available for heat transfer. Smaller ice cubes have higher surface area to volume ratio compared to the large ice block. Hence they absorb heat at a faster rate and melt faster. Here is a more detailed explanation and answer.

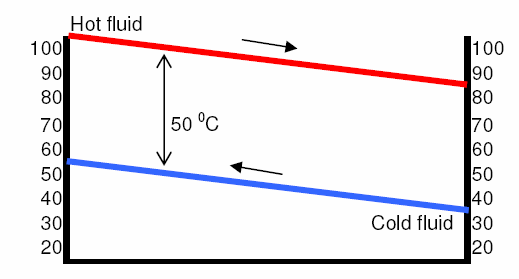

Q: How do you calculate the LMTD when delta T on both ends of a shell & tube exchangers is the same, i.e. 50 deg C?

Ans: This is another trick question. Normally, you would take the LMTD equation and plug the delta T values in that equation and get the answer within a minute.

But, take a closer look at the LMTD equation that you will not get a correct answer when ΔT1 = ΔT2. As you would end up getting a zero (0) in the denominator of the LMTD equation!

No need to panic right away. Take a step back and think what LMTD is really about? It is a MEAN temperature difference. So it actually represents an average of ΔT values at different ends of the exchanger.

So when you have the same ΔT (50 degC), you don't need an average. The LMTD in this case is 50 degC.

Q: Should a fouling or corrosive fluid be put on the shell side or tube side of an exchanger? Why?

Ans: A corrosive / fouling fluid is always preferred to be placed on the tubeside of a shell and tube heat exchanger. This is because the inside surface of the tube bundle is much easier to clean mechanically, than the outer tube surface or inner shell surface.

Q. What is the heat exchanger approach temperature and why is it important?

Ans: Heat exchanger approach temperature, is the difference between required outlet temperature of the process fluid and the temperature at which selected utility is available. A low approach temperature can lead to very high equipment costs for the exchangers. Read more about it here.

Q. When is it preferred to use a finned tube heat exchanger and why?

Ans: Finned tube heat exchangers are characterized by the significantly increased outer tube area. This extra heat transfer surface area is useful when there is a fluid with low 'heat transfer coefficient' or 'temperature difference (ΔT)' on the outside of the tube. Often the finned tube exchangers are used when you have a liquid with high heat transfer coefficient within the tubes and air on the outside.

Piping

If you start working as a process design engineer, you would most likely work in a multi disciplinary engineering team, along with piping, instrumentation, civil and electrical engineers.

As a process engineer you would also need to give inputs to these engineers. For example, in the form of a 'piping and instrumentation diagram (P&ID)' which is commonly prepared by a process engineer. Therefore, it is important for you to have some basic knowledge of these disciplines, including piping.

Therefore you can always expect some piping questions in a process engineering interview.

Q: What is the difference between pipes and tubes?

The main difference between pipe and tube is the critical dimension used to describe the pipe size or the tube size. For pipes, internal diameter (ID) roughly corresponds to the nominal pipe size. For tubes, the outer diameter (OD) roughly corresponds to the tube size.

A more detailed answer is posted here.