The baffle is a metal plate in the form of a segment of a circle with necessary holes to accommodate tubes. Baffles are very important in shell and tube heat exchangers to direct flow as well as to create turbulence. This increases heat exchanger efficiency.

Table of Content:

Why are baffles provided in heat exchangers?

Types of Baffles

Baffle Cut

Baffle Spacing

Baffle Clearance

Why are baffles provided in heat exchangers?

Baffles are used in shell and tube heat exchangers,

- To provide structural support to inner tubes.

- To reduce the mechanical vibration of tubes. This also reduces leakages and failures near tube sheets.

- To direct the shell side fluid in the desired direction over the tubes. This creates turbulence on the shell side.

- To increase heat transfer rate: Due to increased turbulence on the shell side, the convective heat transfer coefficient increases. This results in increased effectiveness of the heat exchanger.

Types of Baffles

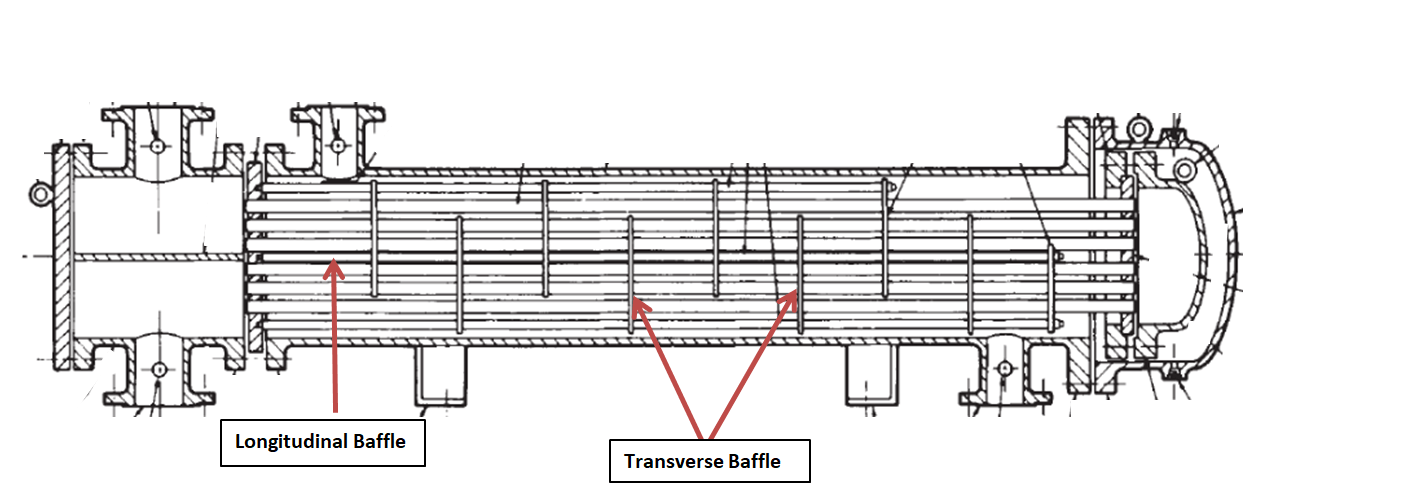

Longitudinal Baffles

These baffles are installed such that they are parallel to the axis of the shell. Longitudinal baffles are used to direct the overall flow direction of shell side fluid. The longitudinal baffles force the fluid to change direction and create a flow path that maximizes heat transfer. It acts as a partition for shell side fluid. Due to this, shell side fluid passes the shell two times. So, generally, these baffles are used where multiple passes of shell side fluid are required.

Transverse Baffles

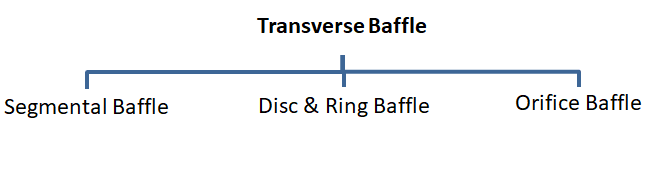

Transverse baffles are arranged such that they are perpendicular to the axis of the shell. There are different types of transverse baffles available.

Segmental Baffle: It consists of partitions, or baffles, that divide the tank into compartments, causing the fluid to flow in a specific direction and preventing short circuits. Types of segmental baffles are discussed below.

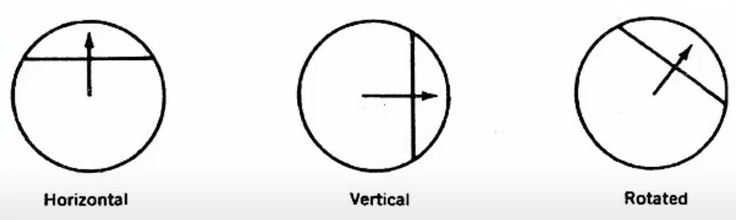

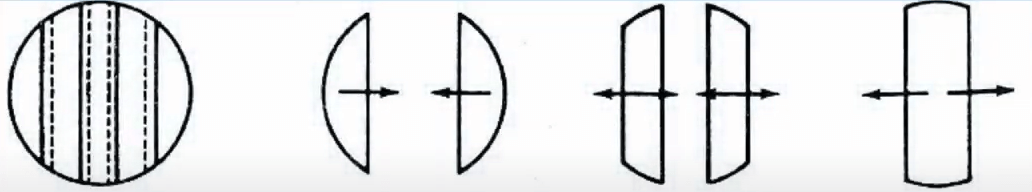

1. Single Segmental Baffle: Single segmental baffles are a type of baffle that consists of a single, continuous piece that divides the tank into compartments.

The cut on the baffle can be horizontal, vertical, or rotated.

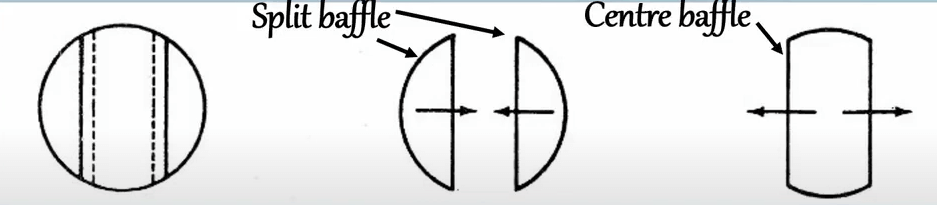

2. Double Segmental Baffle: In this type of baffle, the baffle plate is cut in such a way that we get two parts, the center baffle and the split baffle. There will be a small overlap between the center and split baffle. This overlap will be adjusted by a minimum of one tube row. These baffles split shell side flow in two currents around each second baffle. Due to this velocity of fluid and pressure drop decreases.

These baffles are particularly useful in shell and tube heat exchanger which contains large tube bundles. The double segmental baffles are installed inside the shell to provide a more effective flow division

3. Triple Segmental Baffle: In this type of baffle, the baffle plate is cut in such a way that we get three parts. One center baffle and two split baffles.

In this configuration, all tubes are supported by all baffles. This results in minimal pressure drop and minimum tube vibration.

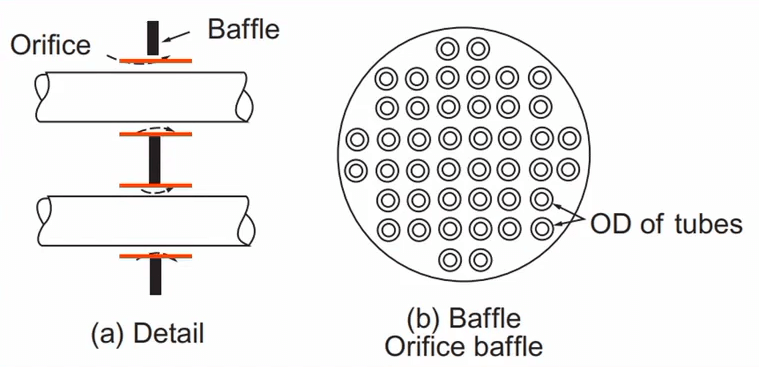

Disc and Ring Baffle: These are also called disc and doughnut baffles. The disc and ring baffle consists of a series of circular discs and annular rings that are installed inside the shell of the heat exchanger.

Disc and ring baffles are composed of alternating outer rings which are also called doughnut-shaped baffle, and inner discs which directs flow radially across the tubes. Usually, the disc should be larger than the doughnut hole.

Orifice Baffle: In this type of baffle, shell side fluid flows through the clearance between the tube outside and the baffle hole. These baffles are rarely used because they are the least efficient. These baffles cannot be cleaned when plugged with dirt and scale. This type of baffle should not be used for fluids that rapidly fall the outer surface, where corrosion and erosion can damage the tubes.

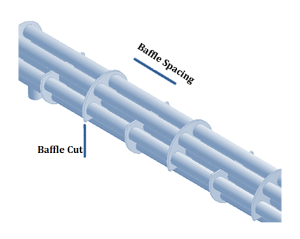

Baffle Cut

Baffle cut refers to the size or opening of the baffle in a shell and tube heat exchanger. It is the distance between the edge of the baffle and the inside wall of the shell, and it determines the amount of fluid that can flow through the heat exchanger.

A smaller baffle cut creates a more restricted flow, increasing the turbulence and heat transfer. While a larger baffle cut allows for a more free flow, reducing turbulence and heat transfer. The optimal baffle cut depends on the specific requirements of the heat exchanger design, such as the fluid properties, the desired heat transfer rate, and the pressure drop tolerance. Baffle cut can vary between 15% and 45% of the shell inside diameter.

Baffle Spacing

The center-to-center distance between adjacent baffles is called Baffle Spacing. The baffle spacing determines the flow path of the fluid, the amount of turbulence generated, and the heat transfer rate within the exchanger.

- A smaller baffle spacing creates more flow restriction and higher turbulence, which can improve the heat transfer rate. Additionally, a smaller spacing also increases the pressure drop across the exchanger, which can negatively affect its performance.

- On the other hand, a larger baffle spacing allows for a more free flow of the fluid, reducing turbulence and the pressure drop, but decreasing the heat transfer rate.

Proper baffle spacing is needed to achieve maximum heat transfer rate with minimal pressure drop. So baffle spacing should not be greater than the inside diameter of the shell as well as it should not be less than one-fifth of the inside diameter of the shell or 2 inch whichever is greater. The optimum baffle spacing is 0.3-0.5 times the shell diameter.

To study optimum baffle spacing in heat exchangers, click here.

Baffle Clearance

There are two types of baffle clearance we have to consider for the design of the baffle. One is baffle-shell clearance, Other is baffle-tube clearance.

Baffle-shell clearance is the minimum distance between the inside surface of the heat exchanger shell and the outside surface of the baffles. Generally, a larger baffle clearance will result in lower pressure drop and better heat transfer performance, but a smaller baffle clearance will provide better fluid mixing and turbulence, which can enhance heat transfer. A typical range of baffle clearance is between 1-5 mm.

Baffle-tube clearance is the distance between the baffle hole diameter and the outside diameter of the tubes. This clearance allows the tubes to be inserted into the baffle with ease. A too small baffle-tube clearance can result in fluid stagnation, poor flow distribution, and reduced heat transfer efficiency. On the other hand, a too large baffle-tube clearance can result in reduced turbulence, which can also reduce heat transfer efficiency. A typical range of baffle to tube clearance is between 1-3 mm.

To check the details of all parts of the heat exchanger, check this post. You can also check the list of all shell and tube heat exchanger parts along with a diagram, here.