An air cooled condenser is a type of heat exchanger that is used to cool and condense hot vapor refrigerant from a refrigeration or air conditioning system. As the name suggests, this type of condenser uses air as the cooling medium instead of water or other liquids.

Table of content:

What is an air cooled condenser?

How does an air cooled condenser work?

Air cooled condenser types

Advantages of air cooled condenser

Disadvantages of air cooled condenser

What is an air cooled condenser?

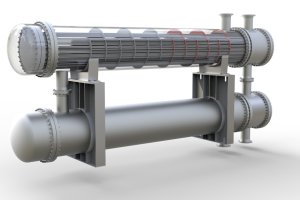

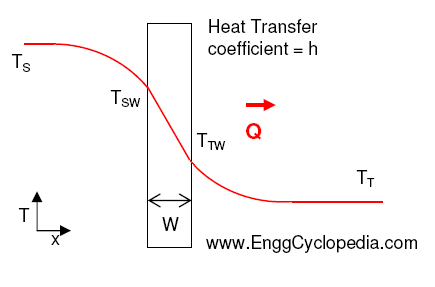

An air-cooled condensers are a type of heat exchanger that is commonly used in refrigeration and air conditioning systems to remove heat from a refrigerant or other working fluid. It operates by transferring heat from the refrigerant to the surrounding air, using a series of tubes or coils that are exposed to a flow of air.

The air flow is typically created by one or more fans that draw air through the coils, removing heat from the working fluid and transferring it to the ambient air. The hot air is then discharged to the atmosphere, allowing the process to continue.

How does an air cooled condenser work?

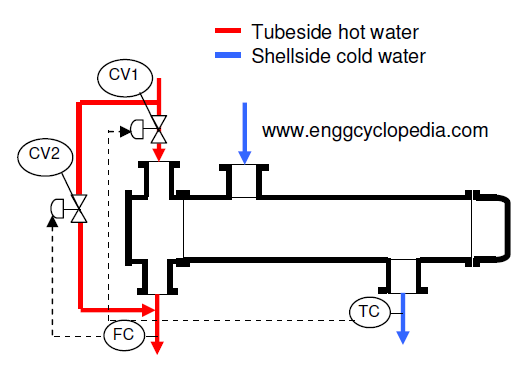

An air-cooled condensers work by transferring heat from a refrigerant or other working fluid to the surrounding air, using a series of tubes or coils that are exposed to a flow of air. The process involves several steps:

- The hot refrigerant or working fluid enters the condenser, where it flows through a network of tubes or coils.

- As the hot fluid flows through the tubes, a fan or fans draw air through the coils, which removes heat from the fluid.

- As the air passes over the coils, it absorbs the heat from the fluid and becomes warmer.

- The now-cooled fluid leaves the condenser and continues through the cooling system, while the warm air is discharged to the atmosphere.

By continuously transferring heat from the fluid to the air, an air-cooled condenser can effectively cool the fluid. This allows it to be used in a variety of applications, including air conditioning and refrigeration systems.

Air cooled condenser types

Air-cooled condensers come in two main types, induced draft and forced draft, which differ in how they move air through the condenser.

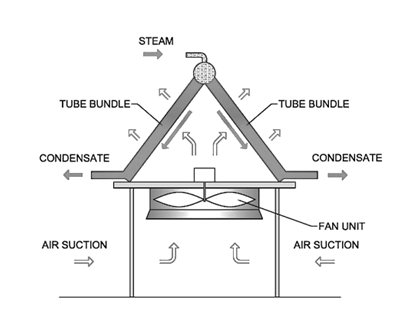

1. Induced draft air-cooled condenser

In this type of condenser, the fans are located at the top of the unit and pull air through the condenser. The air flow is induced by the negative pressure created by the fans, hence the name "induced draft". The steam enters the top of the condenser and flows downward through the tubes, while ambient air is drawn in through the bottom of the unit and moves upward over the tubes. Induced draft air-cooled condensers are typically used in larger power plants and can handle a high volume of steam.

2. Forced draft air-cooled condenser

In this type of condenser, the fans are located at the bottom of the unit and push air through the condenser. The air flow is forced by the positive pressure created by the fans, hence the name "forced draft". The steam enters the bottom of the condenser and flows upward through the tubes, while ambient air is forced in from the top of the unit and moves downward over the tubes. Forced draft air-cooled condensers are typically used in smaller power plants and can handle a lower volume of steam.

Advantages of air cooled condenser

Air-cooled condensers have several advantages over other types of condensers, including:

- Lower Water Consumption: Air-cooled condensers do not require a constant supply of water for cooling purposes, as opposed to water-cooled condensers. This means that they are an excellent option for areas where water is scarce or expensive.

- Low Maintenance Costs: Air-cooled condensers require less maintenance compared to water-cooled condensers, as they don't need to be cleaned regularly and don't have to deal with issues related to water treatment.

- Flexibility in Location: Air-cooled condensers can be located anywhere, as they don't require a nearby source of water. This makes them a popular option in remote areas or in situations where there is limited space.

- Lower Initial Cost: Air-cooled condensers are typically less expensive to install than other types of condensers. They also do not require expensive pumps, water towers, or other water-related infrastructure.

- Environmentally Friendly: Air-cooled condensers do not consume water, making them more environmentally friendly than water-cooled condensers. Additionally, they do not contribute to the growth of harmful bacteria or algae in water, which can be a problem in some water-cooled systems.

Disadvantages of air cooled condenser

While air-cooled condensers have several advantages, they also have a few disadvantages, including:

- Lower Efficiency: Air-cooled condensers are generally less efficient than water-cooled condensers. This is because the temperature difference between the refrigerant and the air is typically smaller than the temperature difference between the refrigerant and the water.

- Higher Operating Costs: Because air-cooled condensers are less efficient, they may require more energy to operate than water-cooled condensers. This can result in higher operating costs over time.

- Noise: Air-cooled condensers can be noisy, especially when they are located close to residential or commercial areas. This noise can be a nuisance to nearby residents or workers.

- Limited Capacity: Air-cooled condensers have a limited capacity compared to water-cooled condensers. This means that they may not be suitable for larger commercial or industrial applications.

- Maintenance Issues: While air-cooled condensers require less maintenance than water-cooled condensers, they may still require regular cleaning to prevent dirt and debris from accumulating on the fins or coils. This can be more challenging in dusty or dirty environments.