An evaporative condenser is a type of heat exchanger that is used to remove heat from a process or system by using the evaporation of water. It is commonly used in refrigeration and air conditioning systems to cool down the refrigerant by exchanging heat with water. Evaporative condensers are known for their energy efficiency and are particularly suitable for use in dry climates.

Table of content:

What is an evaporative condenser?

How does an evaporative condenser work?

Evaporative condenser types

Advantages of evaporative condensers

Disadvantages of evaporative condensers

What is an evaporative condenser?

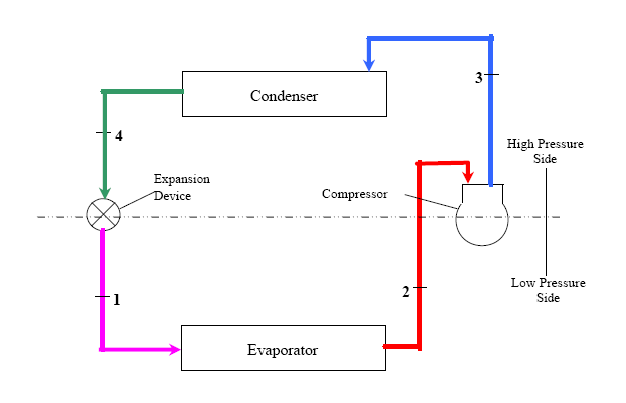

An evaporative condenser is a type of heat exchanger that uses the evaporation of water to remove heat from a process or system. Its purpose is to cool down the refrigerant in a refrigeration or air conditioning system by exchanging heat with water.

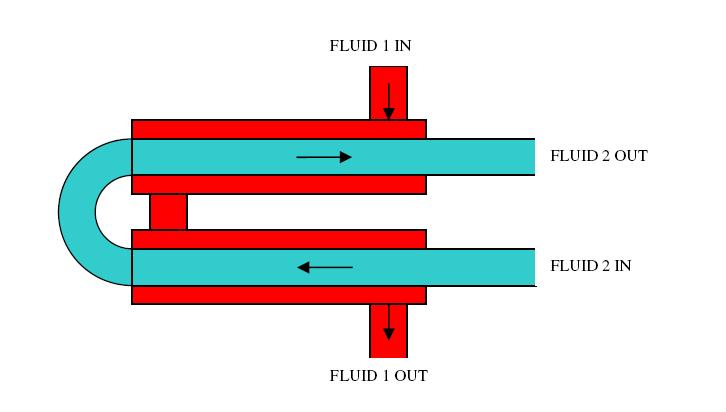

The basic operation of an evaporative condenser involves the circulation of a refrigerant through a coil that is in contact with a water spray. As the refrigerant flows through the coil, it releases heat to the water, which evaporates and removes the heat from the system. The cooled refrigerant then flows back into the system to continue the cooling process.

How does an evaporative condenser work?

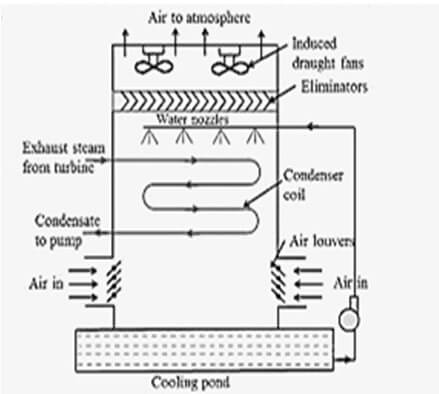

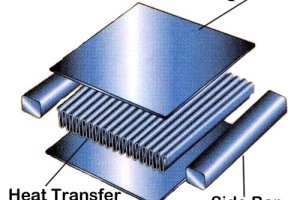

The components of an evaporative condenser include the refrigerant coil, water spray system, fan, and water supply system.

The refrigerant coil is typically made of copper or aluminum and is designed to maximize heat transfer between the refrigerant and water.

The water spray system is used to distribute water evenly over the surface of the coil, allowing for efficient heat transfer.

The fan is used to draw air through the coil, which helps to increase the rate of evaporation and remove heat from the system.

The water supply system provides a continuous flow of water to the spray system, ensuring that there is always enough water to evaporate and remove heat from the system.

The operation of evaporative condenser is as follows.

- The fan draws warm air from the surrounding environment through the coil, which is cooled by the evaporation of water.

- As the warm air passes over the cooled coil, the heat is transferred to the water, which then evaporates and removes the heat from the system.

- The cooled refrigerant then flows through the coil and absorbs more heat from the system, continuing the cooling process.

The basic operation of an evaporative condenser is a highly efficient and effective way to remove heat from a process or system, making it a popular choice for cooling applications in various industries.

Evaporative condenser types

Forced draft and induced draft are two types of fan systems that can be used in evaporative condensers to move air through the unit.

Forced Draft Evaporative Condenser

In a forced draft evaporative condenser, the fan is located at the inlet of the unit, and it forces air through the condenser coils and across the heat exchange surface. This creates positive pressure inside the unit, which helps to prevent the infiltration of outside air and reduces the risk of contaminants entering the system. The air is pushed through the unit, and the warm water is distributed over the condenser coils.

The warm water evaporates as it flows over the coils, and the heat is transferred from the refrigerant to the water. The cooled water is then collected at the bottom of the unit and circulated back through the system.

Forced draft systems are typically used in smaller evaporative condensers and can provide a more consistent airflow and heat transfer. They are also generally easier to maintain since the location of the fan allows for easier access to the components.

Induced Draft Evaporative Condenser

In an induced draft evaporative condenser, the fan is located at the outlet of the unit, and it draws air through the condenser coils and across the heat exchange surface. This creates negative pressure inside the unit, which can help to reduce the amount of heat that is lost through the inlet and outlet openings. The air is pulled through the unit, and the warm water is distributed over the condenser coils.

The warm water evaporates as it flows over the coils, and the heat is transferred from the refrigerant to the water. The cooled water is then collected at the bottom of the unit and circulated back through the system.

Induced draft systems are typically used in larger evaporative condensers and can provide more efficient heat transfer and lower energy consumption. However, they can be more difficult to maintain since the location of the fan may require more complex access to the components.

Advantages of evaporative condensers

Evaporative condensers offer several advantages compared to other types of condensers. Some of the advantages are discussed here.

- Evaporative condensers are highly energy-efficient and can help to reduce overall energy consumption in cooling systems. Since they use water evaporation to transfer heat from the refrigerant to the air, they require less energy to operate compared to air-cooled or water-cooled systems.

- Evaporative condensers are typically smaller in size compared to other types of condensers, which can be an advantage in situations where space is limited.

- Due to their energy efficiency, evaporative condensers can help to reduce operating costs and lower overall system maintenance costs.

- Since evaporative condensers operate at a lower pressure compared to other types of condensers, they require a lower refrigerant charge, which can help to reduce costs and minimize the risk of refrigerant leaks.

- Evaporative condensers use water as the primary heat transfer medium, which is a more environmentally friendly option compared to some other cooling systems that use chemical refrigerants.

Disadvantages of evaporative condensers

While evaporative condensers offer several advantages, there are also some potential disadvantages to consider. Some of the disadvantages are discussed here.

- Evaporative condensers require a reliable source of clean and fresh water to operate effectively. If the water source is not of good quality, it can lead to scaling, corrosion, and fouling of the system components.

- Evaporative condensers require regular maintenance to ensure optimal performance and prevent issues such as scaling and fouling.

- In high humidity environments, the cooling efficiency of the system may be reduced, while in extremely low humidity environments, the evaporative cooling process may not work at all.

- While evaporative condensers can offer long-term energy savings and lower operating costs, the upfront installation costs can be higher compared to other types of condensers.

- The operation of the fan in an evaporative condenser can produce some noise, which may be a consideration in noise-sensitive environments.

- In colder climates, evaporative condensers may require additional freeze protection to prevent damage to the system components during freezing temperatures.