A coil heat exchanger is a type of heat exchanger that consists of a coil-shaped tube or multiple tubes wrapped around a core. The coil heat exchanger works by circulating hot or cold fluid through the coil, which transfers its heat to or from the surrounding environment. The heat transfer occurs through the walls of the tubes, which act as the heat exchange surface. Depending on the application, the fluid flowing through the tubes can be a liquid or a gas.

Table of content:

1. What is a coil heat exchanger?

2. How coil heat exchangers work?

3. Types of coil heat exchangers

4. Advantages of coil heat exchangers

What is a coil heat exchanger?

Coil heat exchangers are a type of heat exchanger that uses a coiled design for heat exchange. They consist of a single or multiple tubes arranged in a coil shape, which allows for efficient heat transfer in a compact design.

The fluid flows through the tubes and exchanges heat with the surrounding environment, either heating or cooling it as required. The basic functionality of coil heat exchangers is the same as other types of heat exchangers, but their unique design offers advantages in certain applications.

How coil heat exchanger works?

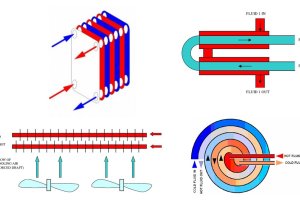

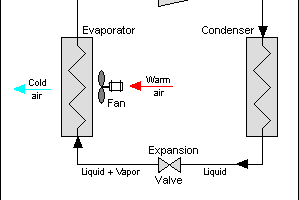

Coil heat exchangers work by allowing a fluid to flow through a coiled tube while exchanging heat with the surrounding environment. The heat transfer process occurs through conduction, convection, or radiation, depending on the specific application.

In a typical coil heat exchanger, the hot or cold fluid flows through the tubes while the surrounding environment, such as air or water, flows around the outside of the coil. The heat is transferred from the fluid to the surrounding environment, either heating or cooling it as required.

The efficiency of the heat transfer process depends on several factors, including the fluid flow rate, temperature difference between the fluid and the surrounding environment, the thermal conductivity of the tube material, and the surface area of the tubes. Higher fluid flow rates and larger temperature differences generally lead to more efficient heat transfer.

The tube material also plays a critical role in heat transfer efficiency. Materials with high thermal conductivity, such as copper or aluminum, are often used in coil heat exchangers. These materials allow heat to transfer more quickly from the fluid to the tube surface, increasing the overall efficiency of the heat exchanger.

Other factors that affect heat transfer efficiency include the fluid viscosity, pressure drop, and fouling. Higher viscosity fluids require more energy to flow through the tubes, which can reduce the heat transfer efficiency.

Types of coil heat exchangers

There are several types of coil heat exchangers, each with its own unique design and advantages. Some of the most common types of coil heat exchangers include:

Single-tube coils: These consist of a single tube that is coiled to form a helix. They are typically used in small-scale applications and have a simple design, making them easy to manufacture and maintain. Single-tube coils are simple to manufacture and maintain, but they have a limited heat transfer area and are not suitable for high-volume applications.

Multi-tube coils: These consist of multiple tubes arranged in a coil shape. They offer a larger heat transfer surface area than single-tube coils, making them more efficient in heat transfer. Multi-tube coils offer a larger heat transfer surface area, but they can be more difficult to clean and maintain.

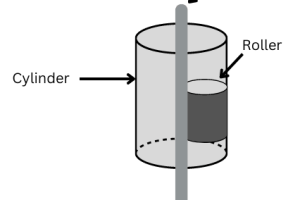

Helical coils: These consist of a single tube that is coiled in a helix shape, creating a more complex flow path for the fluid. The helical design increases the heat transfer area, making it more efficient than single-tube or multi-tube coils. Helical coils offer the most efficient heat transfer, but they are more complex to manufacture and may be prone to fouling.

Advantages of coil heat exchangers

Coil heat exchangers offer several advantages over other types of heat exchangers. Some of these advantages are listed here.

High efficiency: The large number of closely aligned tubes in the coil design provides a large heat transfer area, resulting in a higher heat transfer coefficient and greater heat exchanger efficiency.

Compact and lightweight design: The closely packed tubes make these exchangers very compact and lightweight, and their vertical orientation further reduces the amount of space they take up. This compactness and lightweight design make them easier and less expensive to install, and also contributes to their flexibility in terms of model types and configurations.

Flexibility: As they can be used with a wide variety of temperatures, flows, and pressures. This makes them suitable for use in a range of applications and environments, providing greater overall value.

Low maintenance: The structure of the tubes allows for turbulent fluid flow, which minimizes fouling and scale buildup, and they can be easily removed from the piping system for flushing if necessary.