When troubleshooting control valve, generally process engineers should use following steps

- Get the control loop function test performed and get the logic verified. If some malfunction in the control loop or logic, then get it corrected.

- Get the original design calculations and rated Cv information

- Check the current operating conditions and try to locate current situation between original design cases.

- If the current operation is too far from original design cases then perform the sizing (Sizing of control valve) to estimate the current Cv. Compare the calculated Cv against the design cases and find out the current Cv represents how much opening. If current opening is in between 10% and 90% (ideal healthy range is 15-85% for design cases for installed control valve, it can be relaxed little bit) then valve can still function look for other mechanical damage like

- Malfunction in the actuator can cause erratic behavior. Look for loading pressure connection is proper as well the tubing supplying the Air or gas is not leaking.

- Check for suitability of valve for selected for service or even service has changed over period from clean service to fluid with solids content.

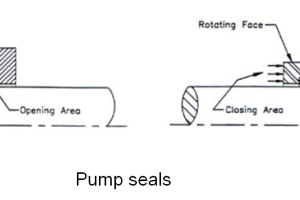

- Packaging damage can also lead to malfunction, check packing conditions and last packing replacement record.

- Check for the actuator spring function, if the spring has lost tension then also it might lead to not able to proper control.

- Wear and tear in the trim (are common phenomena observed), this can alter the characteristic of the selected valve. Look for the damage to the valve plug, cage and seat for any damage. If damage is observed then get the repair done from the valve supplier.

- If current Cv calculations indicated that Cv is either too small or too big for current operations then perform the Cv calculations with current set of data as well as expected future operations and get control valve supplier confirmation quote and replace the valve trim suited to new requirement. If the control valve vendor responded back by saying this valve can be used for revised Cv data then replace the control valve.