Control valves are mechanical devices used in a variety of industries to regulate and control the flow of fluids such as gas, steam, or liquid. Control valves work by opening or closing to regulate the flow of fluid through a pipe or other conduit. The valve is typically controlled by an actuator that responds to a signal from a controller, such as a flow meter, pressure sensor, or temperature sensor.

Table of content:

1. What are control valves?

2. Parts of Globe Valve

What are control valves?

Control valves are mechanical devices used to regulate and control the flow of fluids, such as gases, liquids, or steam, through a pipe or other conduit. They are used in a variety of industries, including oil and gas, chemical processing, power generation, and water treatment.

Control valves work by opening or closing to regulate the flow of fluid through a pipe. They are typically controlled by an actuator that responds to a signal from a controller, such as a flow meter, pressure sensor, or temperature sensor.

There are several different types of control valves, including globe valves, ball valves, butterfly valves, and diaphragm valves. Each type of valve is designed to meet specific application requirements, such as high pressure, high temperature, or corrosive fluids.

Control valves can be used for a variety of purposes, such as maintaining a constant flow rate, regulating pressure, or controlling the temperature of a fluid. They play a critical role in ensuring the safe and efficient operation of industrial processes.

Parts of Globe Valve

Control valves are typically composed of several key components that work together to control the flow of fluid in a system. Following are critical parts of globe type control valve and their information.

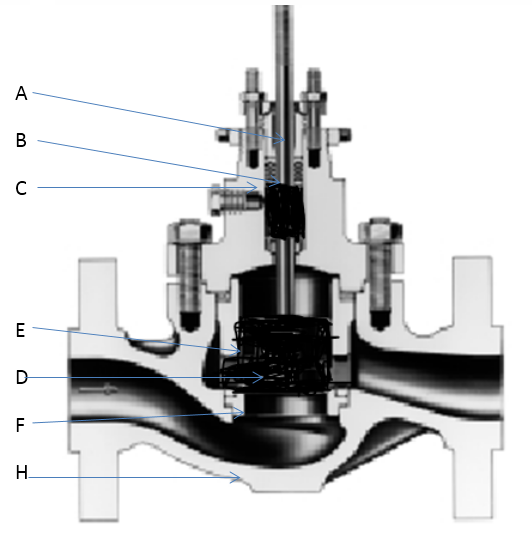

Following figures given details of valve body parts -

A. Plug stem

Plug stem is the potion of valve which connects the actuator steam and the valve. The guiding action from actuator is translated to valve plug. Plug stem takes all the force of opening and closing of valve and is prone to damage early. Hence, proper plug stem selection must.

B. Packing

Packing is the portion surrounding the plug stem and this prevents the fluid from leaking. As this is surrounding the plug stem, this is one item which needs regular inspection and likely change-out during planned shutdown or turnaround works.

C. Bonnet

Bonnet provides the enclosure to the valve plug stem and packing. This is upper part of valve body.

D. Valve plug

Valve plug is the portion which opens and closes to regulate the control valve function. Type of valve plug is critical avoid leakage from the valve.

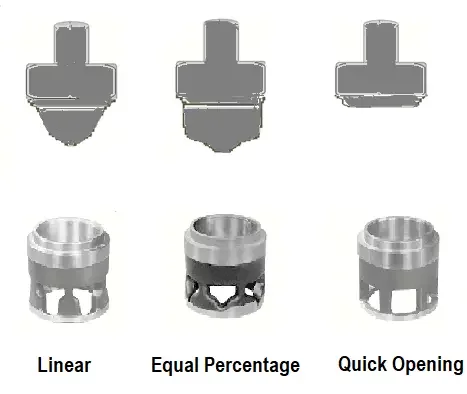

E. Cage

Cage is between the valve plug and the body of the valve. Type of the cage determines the leakage from the valve plug to the bonnet. To meet the desired leakage class, cage plays critical role.

F. Seat

Seat is the locations where valve plug or disc is rests in close position. The soft or hard seal is based on the pressure, temperature and type of fluid to be handled. Soft seats gives less leakage rates where as hard seats gives higher leakage.

G. Valve Trim

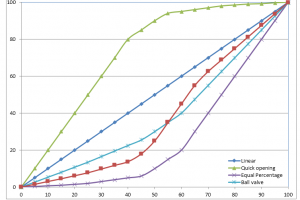

Valve trim is the combination of the valve plug or disc, cage and seat. The trim of the control valve decided rated Cv, leakage class and valve characteristics. Trim is part of control valve, which can be customized based on the requirements.

Check this post to explore the significance of trim in valve system along with types of trims in valve systems and valve trim components.

H. Valve body

Valve body is the lower part of valve which is holds the pressure of fluid and is most heavy part of the valve. Valve body is connected to the bonnet and provides housing to valve internals.

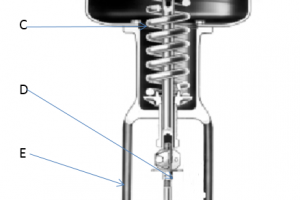

Further opening of a control valves is controlled via its actuator. Read this details post on how actuators work and understand how they are constituted.