Crude oil is naturally occurring fossil fuel deep within Earth's crust. It is complex mixture of hydrocarbons. Crude oil exploration and production refers to the process of locating and extracting crude oil from underground reservoirs. This involves several stages and use of various techniques. Take a detailed look at these techniques along with the stages involved in crude oil exploration and production.

Table of content:

1. Crude Oil Production Equipment

1.1. Casing Strings

1.2. Production Tubing

1.3. Riser

1.4. Slug Catcher

1.5. Well Completion

1.6. Wellhead

1.7. Multiphase Flow Meter (MPFM)

2. Crude Oil Production Instrumentation

2.1. Choke valves

2.2. Gas lift valves

2.3. Subsurface Safety Valves (SSSV)

3. Crude Oil Extraction Process

3.1. Gas Lift for Oil Wells

4. Terminology

4.1. Gas to Oil Ration (GOR)

4.2. Productivity Index for Oil Wells

4.3. Water Cut

Crude Oil Production Equipment

Crude oil production requires specialized equipment to extract, process and transport crude oil safely and efficiently. Crude oil production equipments are components or tools used in the extraction and processing of crude oil from oil wells. A few types of equipment are studied in this section.

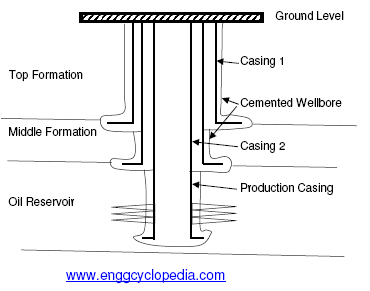

Casing Strings

Casing string is a connected series of steel pipes which runs through the wellbore from wellhead to the oil reservoir. Sections of pipe are connected with each other using couplings, to suit a particular wellbore. Normally length of a typical pipe section is 40ft or 12m. These sections are male threaded on both ends are connected to each other by couplings which are female threaded on both ends.

Production Tubing

Production tubing passes through the wellbore up to the reservoir and is responsible for transporting the reservoir fluids to surface. While selecting production tubing, the wellbore geometry, properties of reservoir fluids and production characteristics of the concerned reservoir have to be considered. Production tubing along with other completion components such as casing makes up the production string.

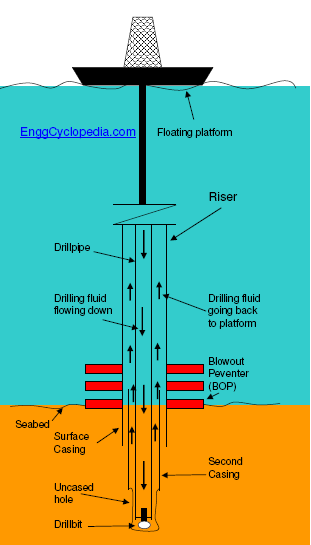

Riser

Riser is a pipe which connects an offshore oil well to the associated drilling platform. A riser runs up starting from the seabed up to the drilling platform. Based on the whether the wellhead and Blow Out Preventer (BOP) are located on the seabed or on the drilling platform, the associated riser can be classified in two types.

1. Marine Drilling Riser

2. Tie-back Drilling Riser

Slug Catcher

Slug catcher is a static equipment used in the upstream oil production facilities to minimize the slug from oil and gas pipeline. Fluids extracted from oil and gas reservoirs contain crude oil, natural gas, water, salts etc.

The multiphase flow in a pipeline often leads to formation of slug flow. This multiphase flow is received in a large vessel in the crude oil processing and storage facilities where the oil, water and gases are separated to remove the slug, hence the name.

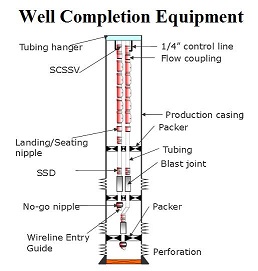

Well Completion

A well completion for oil production of wells, refers to the assembly of tubulars, packers, and other tools installed beneath the wellhead in the production casing. A well completion provides means for separation of different zones, by separating the tools and equipment that provide control and safety of two different flow paths.

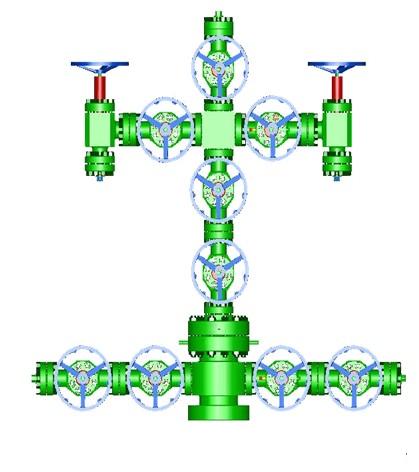

Wellhead

Wellhead consists of components of an oil well which are located above the surface. Wellhead acts as an interface between the casing strings in oil wellbore and surface facilities. Well head provides suspending point for the casing strings running through the wellbore and also acts to contain the pressure inside the casing strings.

Multiphase Flow Meter (MPFM)

A multiphase flow meter is used to measure the flowrates of produced crude oil, water and gas phases from an oil production well. A multiphase flowmeter can be thought of as a scaled down assembly of test separator and corresponding flow meters.

Crude Oil Production Instrumentation

Instruments play a crucial role in ensuring safe and efficient extraction and production of crude oil. Some common types of instrumentation used in crude oil production is discussed in this section.

Choke valves

Choke valve is a type of control valve, mostly used in oil and gas production wells to control the flow of well fluids being produced. Another purpose that the choke valves serve is to kill the pressure from reservoir and to regulate the downstream pressure in the flowlines. Typically oil and gas producing wells have two choke valves in series, one non-regulating choke valve and one regulating choke valve downstream to the non-regulating choke valve.

Gas lift valves

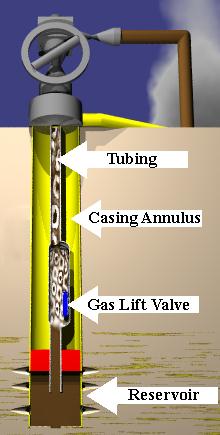

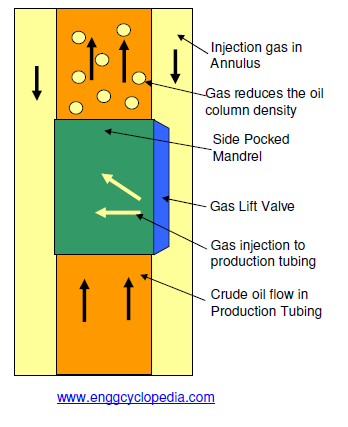

Gas lift valves are used in a gas-lift system to control the flow of lift gas from annulus around the production tubing to the production tubing. The gas lift valves are located in the gas lift mandrel. Gas lift mandrel provides communication with the lift gas supply in the tubing annulus.

Subsurface Safety Valves (SSSV)

To protect the surface facilities in case of emergency, the wellbore is isolated from surface facilities using a subsurface safety valve (SSSV). Hence such a safety valve needs to be fail safe in order to isolate well bore in any kind of system failure or damage to surface production, control and safety facilities.

Crude Oil Extraction Process

Gas Lift for Oil Wells

Gas lift is an artificial-lift method for enhancing crude oil recovery from a reservoir. The gas injected in the oil column reduces the effective density of oil in production tubing, thus reducing the hydrostatic pressure of the oil column in the well. The reduced pressure of the oil column above the reservoir allows the reservoir fluids to enter the oil well bore at a higher flow rate. Gas lift can be either continuous or intermittent, depending on the productivity of the concerned wells.

Terminology

Few important terminologies used in crude oil exploration and production are discussed here.

Gas to Oil Ration (GOR)

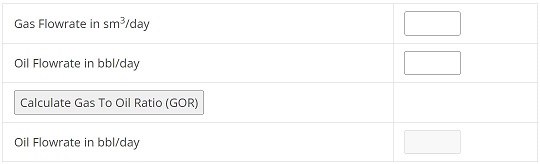

Gas to Oil Ratio (GOR) is a commonly used term in the crude oil exploration and production industry. GOR is the ratio of volumetric flow of produced gas to the volumetric flow of crude oil for crude oil and gas mixture sample.

Productivity Index for Oil Wells

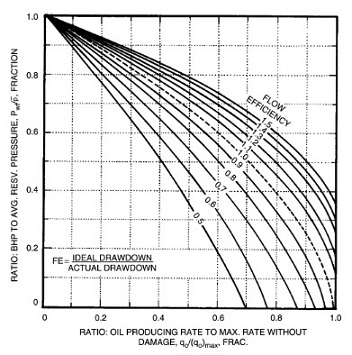

With reference to the oil and gas production wells, the term ‘Productivity Index’ is an indicator of ability of the reservoir to produce fluid flow in relation to the reservoir pressure. The productivity index can be mathematically expressed as the ratio of volumetric flow produced by a well (bbl/day) to the pressure loss between reservoir and bottomhole (psi).

PI = Q/(PR – PBH) bbl/day/psi

Water Cut

Water cut for crude oil refers to the mass percentage of water in all the liquids, i.e. crude oil plus water. Water cut is an important parameter along with the ‘Gas to Oil Ratio’ (GOR) of a crude oil to clearly indicate the water content in reservoir fluids.