Purpose of steam blowing

Cleaning by steam blowing is carried out essentially for steam circuits (i.e for steam generating boilers, steam heated exchangers, steam turbine upstream piping or other steam lines). Due to problems of condensation of steam or draining of condensate, this type of cleaning has to be used with the utmost care, as it can potentially create vacuum in the equipments being cleaned.

The purpose of blowing or cleaning the steam lines prior to starting up a new unit is to remove any foreign matter remaining in the equipment (i.e. superheater) and steam piping after installation is completed.

On older units the need for steam line blowing should be considered following major pressure parts repairs, where the possibility of introduction of foreign material into the system exists.

Since prevention of damage to the plant steam system is the prime concern, the responsibility for determining the effectiveness of the steam line blowing operation rests with the plant operator.

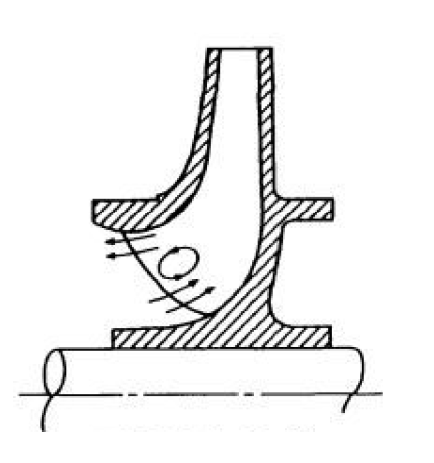

The principle behind blowing steam to clean the lines is that the thermal cycling (heating/cooling) and high velocity gas flowing through the line will "shock" the pipe to break the mill scale and weld slag away from the pipe wall. Ideally, steam blowing should be done prior to the system being insulated to maximum the thermal cycling of the equipment. If the system is insulated, a greater time between consecutive steam blowing operations may be necessary to allow the system to cool.

Steam Blowing Procedure

- Before putting steam into the system, the control valves, turbine meters, instruments, vacuum ejectors and strainers etc. should be removed or blinded off. The steam headers should be slowly warmed up, one header at a time, while expansion of the line is observed. Condensate must be drained manually to prevent steam hammering. The headers should now be blown using a low pressure, high-velocity sweep as explained hereafter. Wherever allowed, only low pressure steam to be used if available at temperatures not exceeding 1200C.

- When the headers are warm, the drain valves should be opened, blown vigorously for a few seconds before closing. Each drain valve lateral to header, exchangers, or service lines should be blown in the same manner, usually not more than one at a time. Condensate lines may be cleaned in the same manner as steam lines. A temporary movable silencer could be used to avoid exceeding noise level limitations during the steam blowing operation, if necessary.

- When blow-down of the steam system is completed, equipment that was removed prior to the blow-down can be reconnected.

Checking the completion and effectiveness of steam blowing

- Target plates of aluminum or other metal will be located at the vent point during steam blowing. The impact on the aluminum or other MOC target located at the vent point during steam blowing will be checked.

- Blowing of the piping system will be considered completed and cleaned upon two consecutive targets after blowing, resulting in less than two pits per square cm with a maximum diameter of 0.3 mm are present on the target plates.

- When blowdown of the steam system is completed, traps and other equipment that were removed prior to the blow-off are reinstated. The system can then be reheated and placed in service, after it cleared the steam test.

General pre-cleaning procedure

- Check all pipe anchors and guides for adequate support of piping, including the temporary vent pipe.

- Ensure that all lines have been inspected and hydro tested.

- Remove all control valves, desuperheater nozzles, flow elements, thermowells, pressure gauges, orifice plates, pressure relief valves and instruments that may be damaged during the steam blow.

- Ensure all vent pipes have adequate drains and that these drains are routed to a safe location.

- Install temporary pressure gauges as required to monitor the progress of the steam blow and make arrangements for recording these pressure readings.

- Establish adequate radio communication between the control room and the operator at the shutoff valve. Back this up with a system of visual communication, such as lights or flags, since audio communication may be difficult due to high noise levels at the steam shutoff valve.

- Ensure that personnel traffic is controlled in area during steam blow. Ensure that the area near the vent pipe is clear of all personnel during the steam blowing. Protect neighboring equipment from damage due to the steam vents.

- Individuals operating the steam blow valves (especially near the vent pipe) should wear double ear protection.

General procedure for cleaning by steam blowing

- Discontinue all firing and gradually open the temporary blowoff valve, to blow through the steam system and out the temporary blowoff piping. Caution should be exercised to always perform first steam blow at reduced pressure, in order to check out the temporary piping system, its supports, anchors and spacing between supports.

- When the steam drum pressure has dropped to the value corresponding with a 100°F (56°C) saturated steam temperature close the temporary blowoff valve and refire the unit to re-establish blowing conditions.

- Repeat the above cycle until it is considered that cleaning is satisfactory as indicated by inspection of impact specimens during the final blows.