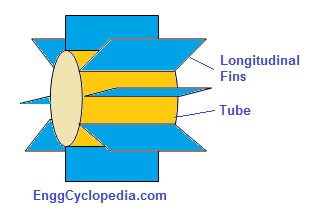

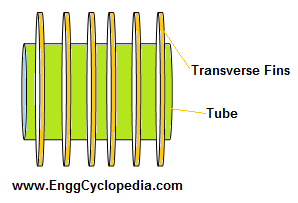

Finned tube heat exchangers are characterized by the radial or longitudinal 'fins' located on the outside of the tubes. The tubes carry a fluid which is the "service" to be heated up or cooled down. On the outside of the tubes there is typically air or can be some other fluid.

Advantage of the finned tubes

The fins on the outside of the tubes result in an incredible increase in the outer surface area of the tubes. This increase in the heat transfer surface area is the single most important feature of this design.

Increase outer surface area is more useful when we need some enhancement on the heat transfer rate on the outer side of the tubes.

Heat transfer through the tube wall

Heat transfer rate through the tube walls is governed by the following equation -

Heat flow through inner tube wall = Q = Heat flow through inner tube wall --------------- at equilibrium

hin×Ain×ΔTin = Q = hout×Aout×ΔTout

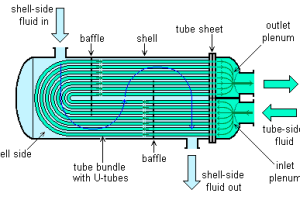

Sometimes we have an imbalance in the heat transfer coefficients on the inside (hin) and outside (hout) of the tubes. When you have a lower hout, that is when you need is larger Aout to keep the balance.

Likewise, you can also have an imbalance in the ΔT. When you have a smaller ΔT on the outside of the tubes, you may need to go for larger outer surface area.

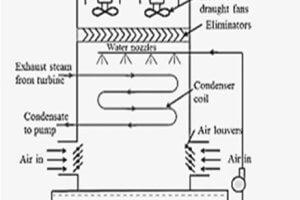

When to use finned tube heat exchangers

Such scenarios can occur when you are using air to cool down or heat up a process fluid in the tubes. Air can have significantly smaller 'heat transfer coefficient' than the liquid inside the tubes. That is when you may opt for a finned tube heat exchanger over a shell and tube exchanger.

Drawbacks of using a finned tube heat exchanger

The biggest problem is with the cleaning and maintenance of the outer surface of the tubes. Because of the fins, mechanical cleaning becomes very difficult and you would have to go for chemical cleaning.

But as long as you have a clean fluid on the outside, you should be fine. Often, you have air on the outside of the tubes, so you don't need to worry about fouling.