Heat exchanger approach temperature is the difference between required outlet temperature of the process fluid and the temperature at which utility is available.

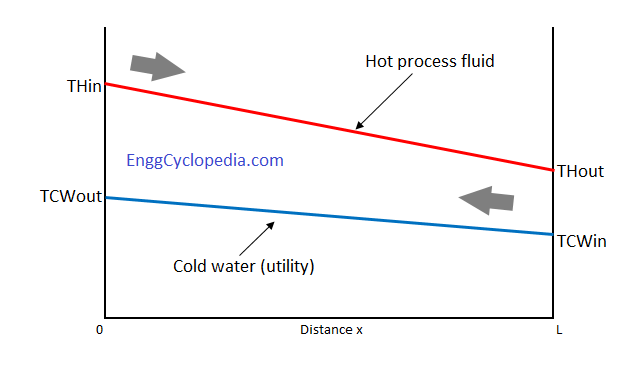

The heat exchanger temperature profile shown in the image above includes two fluids - one hot process fluid and other is cooling water (utility). The process fluid is available at THin and it needs to be cooled down to THout. The cold utility - cooling water is available at TCWin.

Going by the heat exchanger approach temperature definition,

Approach temperature = THout - TCWin

Smaller the value of approach temperature will make it more difficult to achieve THout for process fluid.

Heat exchanger approach temperature concept

The utility can be anything such as - cooling water, steam, hot water, air etc. Normally the inlet/outlet temperature values of the process fluid are given as process requirement. Then we can select an available utility to either heat up or cool down the process fluid as required.

But before buying a new exchanger, it is worthwhile to ask if the available utility is adequate to heat up or cool down the process fluid as required?

Heat exchanger approach temperature indicates the effectiveness of a utility for its intended purpose.

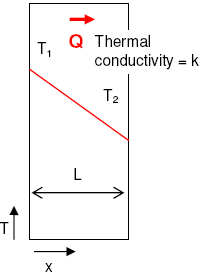

Heat transfer rate (Q) across a heat exchanger is governed by the following equation.

Q = U×A×ΔT

where, U is the heat transfer coefficient,

A is the heat transfer surface area,

ΔT is the temperature difference between hot and cold fluids

If ΔT is small, larger heat exchanger is needed (for large A) to achieve the same heat transfer rate (Q). That means a small approach temperature value will lead to higher cost for the exchanger.

Acceptable approach temperature values

For commonly used utilities in the process industry, following values of approach temperature are acceptable. If approach temperature goes below these limits, it would not make economic sense to use that utility, just to end up designing a very large heat exchanger.

| Utility | Acceptable approach temperature 0C |

|---|---|

| Cooling Water | 8 deg C |

| Air | 14 deg C |

| Steam | 10 deg C |

How to solve the problem of small approach temperature?

But when you do end up with a small approach temperature when sizing a new exchanger equipment, there are a few options that you can try out.

- Check if you can use any other utilities with a bigger approach temperature value.

- Check if you can use a significantly higher flow rate on the utility side. That will result in higher mean temperature difference value, since the outlet temperature of the utility will remain largely unchanged. This can help to keep the heat exchanger smaller in size.

- Check if you can use a type of heat exchanger to maximize the 'U×A' value for overall heat transfer. For example, a finned tube exchanger maximizes the heat transfer area and thereby the overall heat transfer rate.

- In case of shell & tube exchangers, you have the options to select from a variety of exchanger designs to maximize UA value. Follow this design procedure and this list of equations to perform the required calculations.