Pump operations refer to the procedures and activities involved in operating a pump, which is a device used to transfer fluids or gases from one location to another. Pump operations can include the start-up procedure, monitoring, maintenance, shutdown procedures and troubleshooting. Effective pump operations require careful attention to all these points.

Table of content

1. Typical pump start-up procedures

2. Pump Priming

3. Cavitation in pumps

4. Pump Overloading

5. Pump Recirculation

6. Vibration in pumps

7. Troubleshooting for pumps

8. Pump Maintenance

9. Pump Performance Test

10. Reliability coefficient for pumps

Typical pump start-up procedures

Pump start-up procedures are the steps that must be followed to properly start and operate a pump. Starting a pump involves a series of steps to ensure that the pump is functioning correctly and efficiently, and that it is not at risk of damage or failure. These procedures may vary depending on the type of pump and the specific application.

Typical start-up procedures to be followed for start-up of different types of pumps are given on following links.

- Centrifugal Pump Start-up procedure

- Diaphragm Pump Start-up procedure

- Typical start-up procedure for Progressive Cavity Pumps

- Typical start-up procedure for Canned Motor Pumps

- Typical start-up procedure for Sundyne Pumps

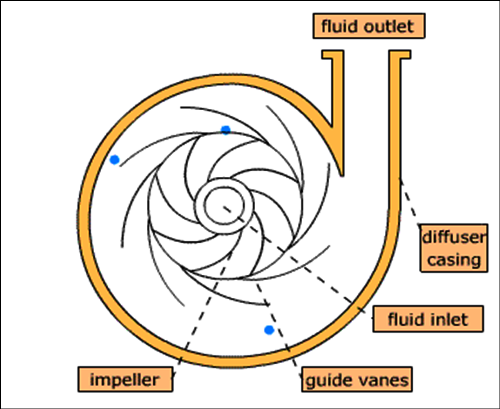

Pump Priming

Pump priming reduces the risk of pump damage during start-up by preventing dry running. For reliable operation, pumps must first be primed by removing air or gases from the suction and impeller eye area and replaced with liquid. Click the button to study pump priming.

Also check,

How to prime centrifugal pumps - Brief guideline / pointers for priming the centrifugal pumps.

Self Priming Pumps - Brief description of how the self priming pumps work.

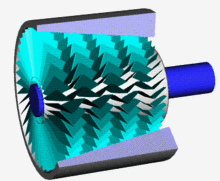

Cavitation in pumps

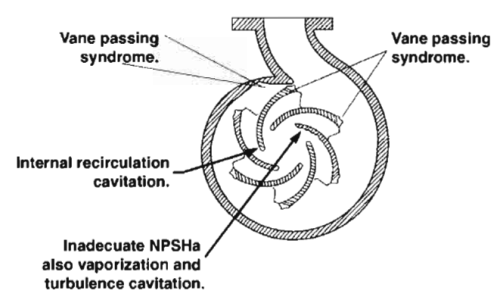

Pump cavitation is the formation and subsequent collapse or implosion of vapor bubbles in a pump. Reason for pump cavitation lies in operation of the pump which deviates from design conditions such as low suction pressure, high liquid temperature etc. Pump cavitation in centrifugal pumps can damage various pump parts. Different types of pump cavitation and basic guidelines to prevent them are discussed in the given post.

Pump Overloading

Pump overloading occurs in centrifugal pumps when the driving motor draws excess current resulting in excess then normal power consumption. Check the theory behind overloading of pumps in the given post.

Also check,

Causes of pump overloading- Various deviations in pump operations from normal conditions can lead to overloading of centrifugal pumps.

Effect of pump overloading - Frequent operation of pumps under overload can damage some parts of the pump.

Pump Recirculation

Internal recirculation in pumps refers to the phenomenon where a portion of the fluid being pumped recirculates back into the impeller instead of being discharged. This can occur when the flow rate is too low, causing the pressure at the impeller inlet to drop below the vapor pressure of the fluid.

When this happens, some of the fluid vaporizes and forms bubbles, which can collapse and cause damage to the impeller and other pump components. This recirculation is different than the minimum recirculation flow required for centrifugal flow and can be a source of serious problems.

Vibration in pumps

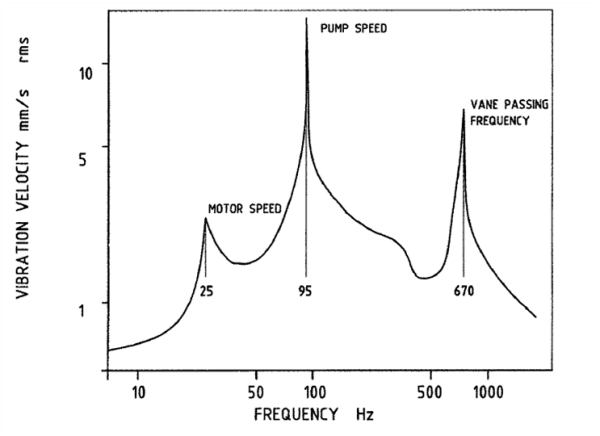

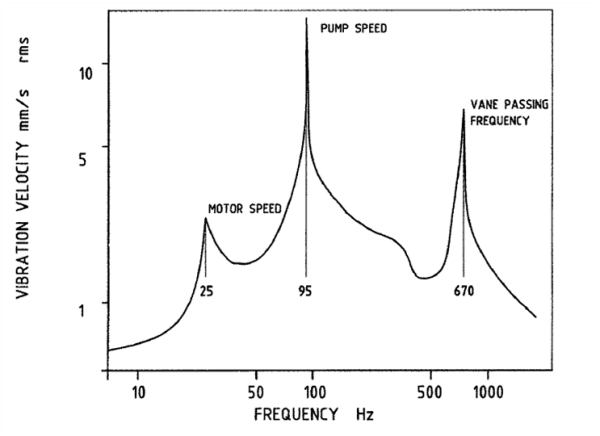

Pump vibration is the rapid back-and-forth movement of the pump or its components, which can be caused by various factors such as unbalanced impellers, misaligned couplings, worn bearings, or other issues.

Vibration can cause impellers to wear out more quickly. This results in reduced pump flow and pressure. Excessive vibration can also cause damage to the bearings, seals, and other parts of the pump, leading to costly repairs or replacements. Study everything about vibration in pumps in the given post.

Also check these posts on Pumps vibrations limits as per international standards and Pump vibration analysis charts.

Troubleshooting for pumps

Problems with pumping equipment cause not only inconvenience, but can also contribute to loss of production. This post lists problems that often occur with pumps with probable symptoms and the possible causes pertaining to them.

Pump Maintenance

Pump operating problems that may cause damage to the pump can be either hydraulic or mechanical. Certain precautions which can be taken to avoid pump damage are discussed along with different inspection schedules and pump maintenance schedules. Tasks to be performed during scheduled inspection and pump maintenance are briefly discussed in this post.

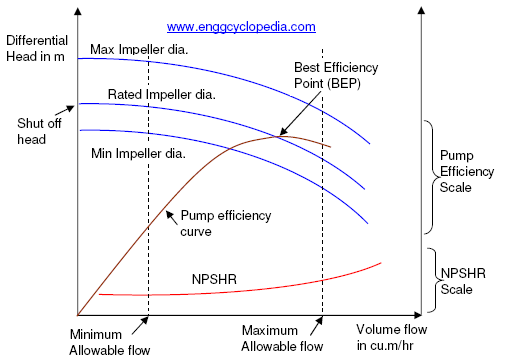

Pump Performance Test

The purpose of pump performance test is to ensure that the actual performance of a pump is close to that predicted by supplier. Pump performance tests are performed to plot the pump performance curves and compare them to curve supplied by the pump manufacturer. Typical steps to be followed to conduct a pump performance test are outlined in this post.

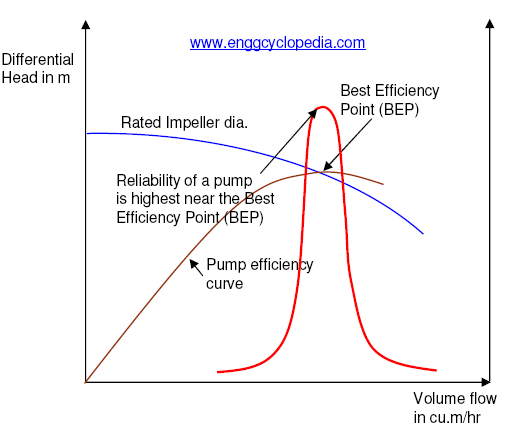

Reliability coefficient for pumps

Many factors influence pump operation and pump reliability such as poor initial installation may cause premature failure due to misalignment, excessive piping strain, improper lubrication, etc. A pump reliability coefficient value of 0.00 means absence of reliability where as reliability coefficient value of 1.00 means perfect reliability. An acceptable reliability coefficient must not be less than 0.90, as less than this value indicates inadequate reliability of pumps. For instance, r =0.95 on a test means that 95% of the test score is accurate while the remaining 5% consists of error.

Check this post to learn about reliability coefficients for pumps.