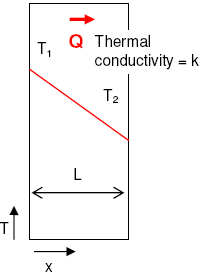

Heat Transfer – Conduction

Heat conduction is the process of transfer of heat energy from one point to another within a solid material or between different materials in physical contact.

Conductive heat transfer occurs when heat is transferred through a material without any motion of the material itself. The heat is transferred from molecule to molecule due to lattice vibration and collision of molecules, transferring heat energy from one molecule to the next. This mode of heat transfer takes place in a stagnant medium.

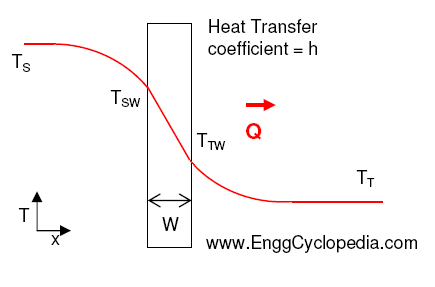

Heat Transfer – Convection of Heat

Heat transfer by convection generally occurs between a fluid and a solid surface and convective heat transfer is accompanied by motion of the fluid. This is the most general description of convective heat transfer. Check the post for more detailed description.

Heat transfer coefficients are a measure of the rate at which heat is transferred between a fluid and a solid surface. It is the proportionality constant between the heat flux and driving force for the heat transfer which is a temperature difference. Check also sample problems to understand the calculation of the heat transfer coefficient in various cases.

The importance of heat transfer surface area

Surface area available for heat transfer is quite an important determinant of the overall rate of heat transfer. Check this post to understand the importance of heat transfer surface area with a simple experiment.

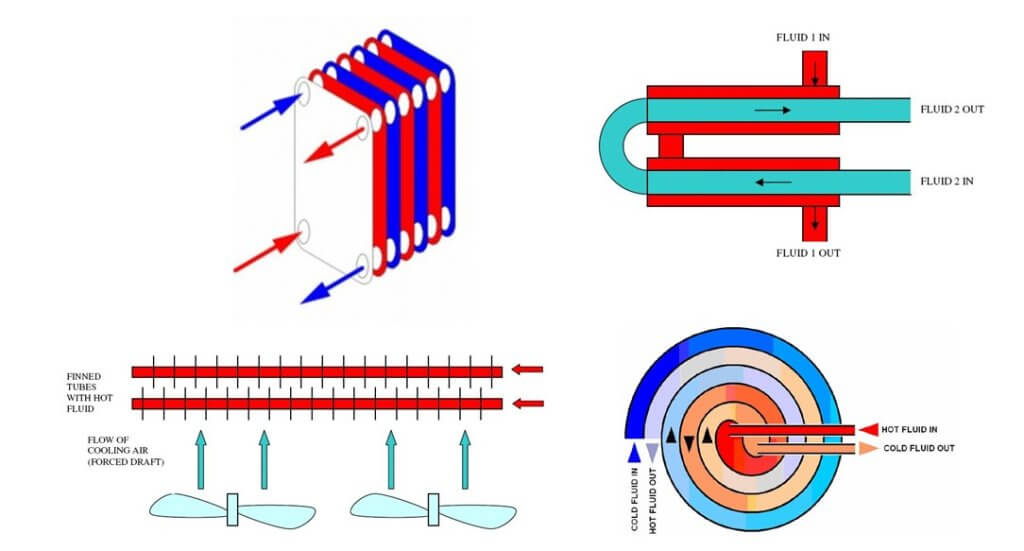

Heat Exchangers

Heat exchangers are essential components in many industries, including chemical, power generation, HVAC, and refrigeration. They play a crucial role in transferring heat from one fluid to another while keeping them separated. Learn everything about heat exchangers including their types, working principle, design & calculations, design software and P&ID symbols in this post.

Heat Exchanger Types

1. Plate and Frame Heat Exchanger

2. Spiral Heat Exchanger

3. Plate-Fin Heat Exchanger

4. Air coolers

5. Double Pipe Heat Exchanger

6. Shell and Tube Heat Exchanger

7. Kettle Type Heat Exchanger

8. Condenser

9. Evaporator

10. Regenerative Heat Exchanger

11. Twisted Tube Heat Exchanger

12. Scraped Surface Heat Exchanger

13. Coil Heat Exchangers

Heat Exchanger Design & Calculations

1. Heat exchanger design

2. Energy balance calculation

3. Calculation of heat transfer coefficient

4. Log mean temperature difference calculation

5. Heat exchanger area

6. Heat exchanger efficiency

7. Heat exchanger fouling factor

8. Heat exchanger approach temperature

9. Shell and tube heat exchanger design procedure

10. Shell and tube heat exchanger equations

11. Shell and tube heat exchanger pressure drop

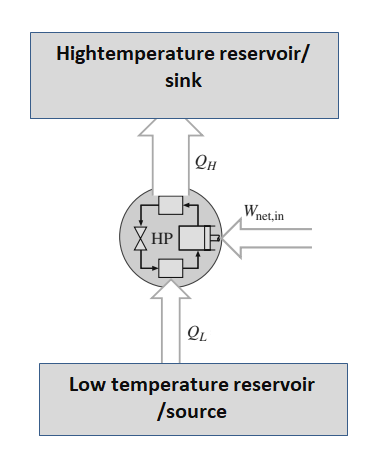

Heat Pumps

A heat pump is a device that transfers heat from one location to another using a refrigerant and a compressor. It can be used for both heating and cooling purposes and operates by compressing a refrigerant gas, circulating it through a heat exchanger to transfer heat, and then allowing the refrigerant to expand, which cools it down.

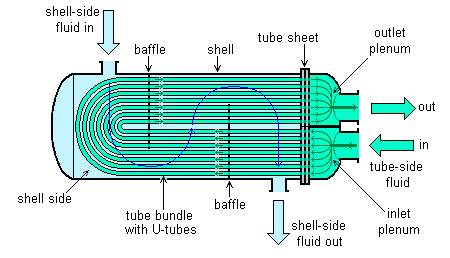

Shell & tube heat exchangers

Shell and tube heat exchangers are very commonly used as preferred heat transfer equipment in the process industry. This type of heat exchangers consists of metal tubes passing through another metal enclosure, which is referred to as the 'shell'. So typically we have a fluid on shell side and anther fluid on the tube side. Heat transfer between the two fluids occurs across the tube walls.

This post contains a comprehensive study of the shell and tube heat exchangers.